Noesis Optimus is an integrated platform and process for optimizing product design. This product integrates various technical tools from different fields such as CAD, multi-body dynamics, finite element dynamics, and computational fluid dynamics into a single automated workflow after the simulation process begins. The software directly explores the design space and optimizes product designs to improve performance and reduce the overall product cost and total design process time.

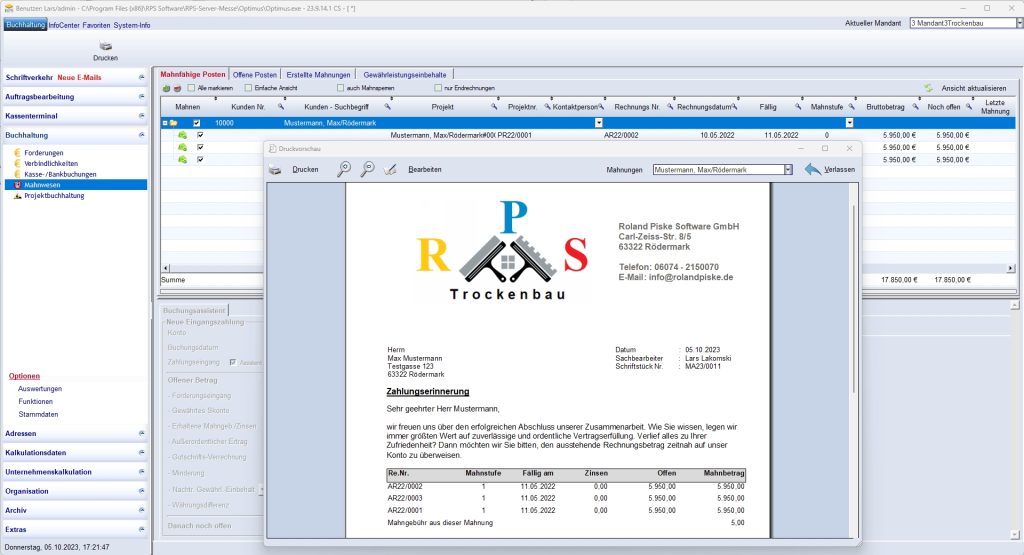

The graphical user interface of this program allows you to create a simulated workflow. Multiple workflows can be created, the simplest of which involves a single simulation program, while more complex processes involve workflows that include multiple simulation programs. These workflows can have multiple branches, and each branch can cover one or more different programs. The workflows created in this software include mechanisms for step-by-step simulations as well as complex and heterogeneous simulations based on cluster computing, with resources from various sources used for cluster computing.

Noesis Optimus is an automation and optimization tool developed by Noesis Solutions that allows users to efficiently design and execute targeted processes while considering all boundary conditions. This program is one of the applications that offers multi-objective optimization. The software enables users to optimize the performance and efficiency of systems and find the best possible configurations for complex problems. This capability allows engineers to consider multiple factors and improve systems to achieve better results. Additionally, this software has the ability to connect with other applications and technical tools, enabling users to transfer data between programs and utilize different structures and systems for optimization. This software is useful and practical for many users as it supports a wide range of systems and popular software in the industry, particularly in product simulation.

The program features a simple and intuitive graphical interface, allowing the user to easily simulate workflows in this environment. It also has advanced automation features that reduce the need for manual input of parameters, helping engineering teams achieve greater efficiency and better results.

In the integrated design and optimization process (PIDO), software tools are required to control all the mechanical functions of the system and various tools (dependent and alternative). Thus, to analyze and improve the design and create connections between the designs and tools of the system, multiple tools are needed.

Optimus – Optimus

Optimus is a leading and recognized PIDO software platform that provides advanced functions for integrated engineering processes, improves reliability and accuracy in defining and validating the design space, optimizes geometry, and enhances the selection and analysis of various designs/projects. To achieve this, this software helps you plan, identify, and solve post-process issues related to your integrated design and optimization process (PIDO).

Optimus provides a workflow design environment for CAE engineers to evaluate alternative designs, optimize product features, and rapidly prototype complex products. The program allows graphical simulation of workflows (for one or multiple programs).

PIDO techniques guide engineering simulations to select the best design among candidate designs, taking into account all design constraints. Optimus users have reported that using this software helps them save, on average, over 30% of design time and improve design performance by more than 10%.

Optimus offers an open architecture for interacting with all technical programs and working with all file formats.

Main features of Noesis Optimus: