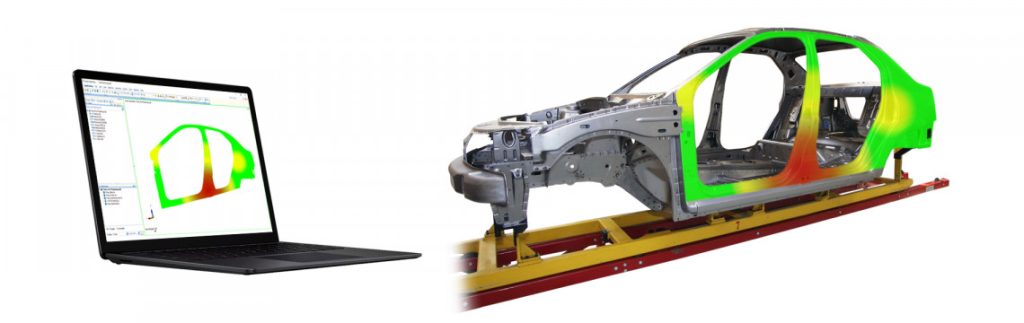

ESI SysWeld is a 3D simulation software designed for welding and heat treatment processes. It provides a fast, responsive, and user-friendly environment for engineers to simulate welding, bonding, and thermal processing, helping to optimize quality and efficiency. The foundation of Sysweld began at a French nuclear engineering company named Framatome at early 1980s. Since then, ESI SysWeld developed with new features like advanced welding, additive manufacturing, artificial intelligence, automation, digital twin integration and etc.

✅ Accurate Welding & Heat Treatment Simulations – Predicts thermal, metallurgical, and mechanical behaviors in welding and bonding processes.

✅ Distortion & Residual Stress Control – Reduces welding-induced deformations and ensures structural integrity.

✅ Optimized Weld Planning – Helps engineers reduce costs, minimize rework, and maintain tight welding tolerances.

✅ Mechanical Load & Thermal Cycle Prediction – Evaluates how mechanical loads and heat effects impact subsequent machining operations.

✅ Geometric Mapping & Subset Management – Supports various geometric transformations and mapping techniques for complex assemblies.

✅ Optimized Convergence Efficiency – Enhances contact configurations for better simulation accuracy.

✅ Process Optimization – Simulates heat treatments, machining, and partial closure with advanced folding mechanisms.

🚀 Reduces Prototyping Costs – Minimizes the need for physical prototypes by simulating welding effects in advance.

🔧 Improves Weld Quality – Ensures optimal weld conditions by predicting thermal and mechanical interactions.

📉 Minimizes Repair Costs – Helps control welding distortions, reducing rework and material waste.

🛠 Enhances Process Efficiency – Shortens welding cycle times by providing real-time optimization insights.

ESI SysWeld is an essential tool for engineers in automotive, aerospace, shipbuilding, and heavy industries, enabling them to optimize welding processes, improve product reliability, and reduce manufacturing costs.