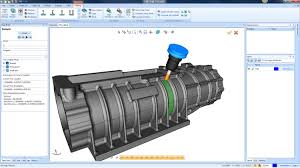

BobCAD-CAM is a comprehensive software that integrates both Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) capabilities.

It is one of the most advanced software solutions for machining simulation, lathe machining, and milling machining using CNC machines.

With its extensive and advanced features, BobCAD-CAM has gained remarkable popularity worldwide, being used in everything from small machining workshops to multinational automotive and aerospace companies for designing and generating CNC lathe and milling code.

BobCAD-CAM

This software is highly effective for industrial design and is especially well-suited for advanced and complex machining such as multi-axis machining and high-speed machining.

BobCAD-CAM is a powerful and ideal software for CNC machining and programming, providing a comprehensive and efficient solution for CNC milling, router machines, and lathe control.

BobCAD-CAM includes a wide array of tools and features for working on 2D to 5-axis machining. It offers an intuitive user interface and a CAD-based 2D and 3D design system, allowing users to create a uniform workspace network in a powerful environment.

BobCAD-CAM interacts with several related software tools such as IGES, AutoCAD, 3DsMax, ACIS, Rhino, SolidWorks, Step7, and others, enhancing machining efficiency and control.