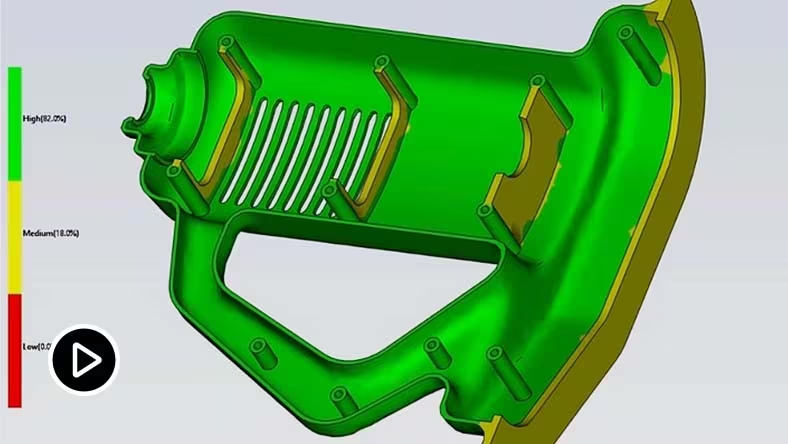

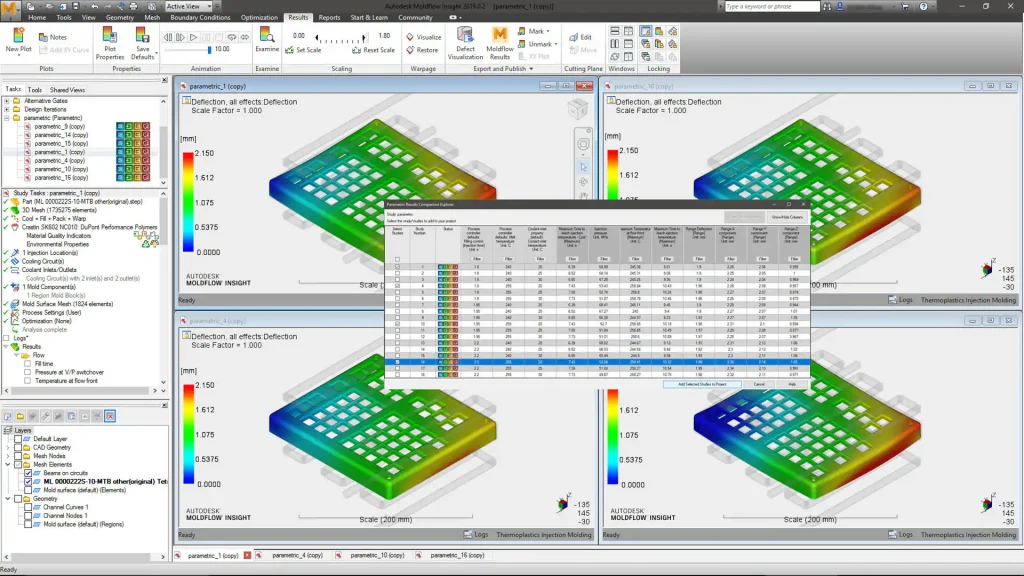

Autodesk Moldflow is one of the most widely used software solutions for plastic injection molding simulation. It is specifically designed to help engineers optimize the plastic injection molding process, reduce costs, and improve the efficiency and quality of manufacturing designs.

This software suite enables engineers to simulate and analyze the injection molding process in great detail, predicting the behavior of materials and parts throughout the manufacturing cycle. It is widely used across various industries where plastic parts are produced, such as automotive, consumer products, and electronics.

Autodesk Moldflow is an indispensable tool for engineers and manufacturers in the plastic injection molding industry. Whether you’re designing consumer products, automotive parts, or electronic housings, Moldflow provides critical insights to optimize designs, improve quality, reduce production costs, and accelerate time to market. With its extensive material library, seamless CAD integration, and powerful simulation capabilities, Autodesk Moldflow helps ensure that the molding process is as efficient, cost-effective, and environmentally friendly as possible.