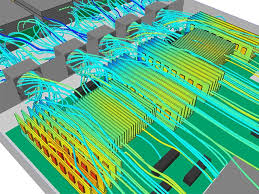

FloTHERM XT is a product from the famous company Mentor Graphics (now acquired by Siemens), specifically designed for simulating flow and heat transfer mechanisms in electrical components and circuits.

The CAD-based user interface is used for complex and custom geometries, enabling users to quickly create the desired product.

This software has significant advanced modeling capabilities with CAD and includes libraries and SmartParts for both geometric and non-geometric components, allowing users access to more settings and features for modeling.

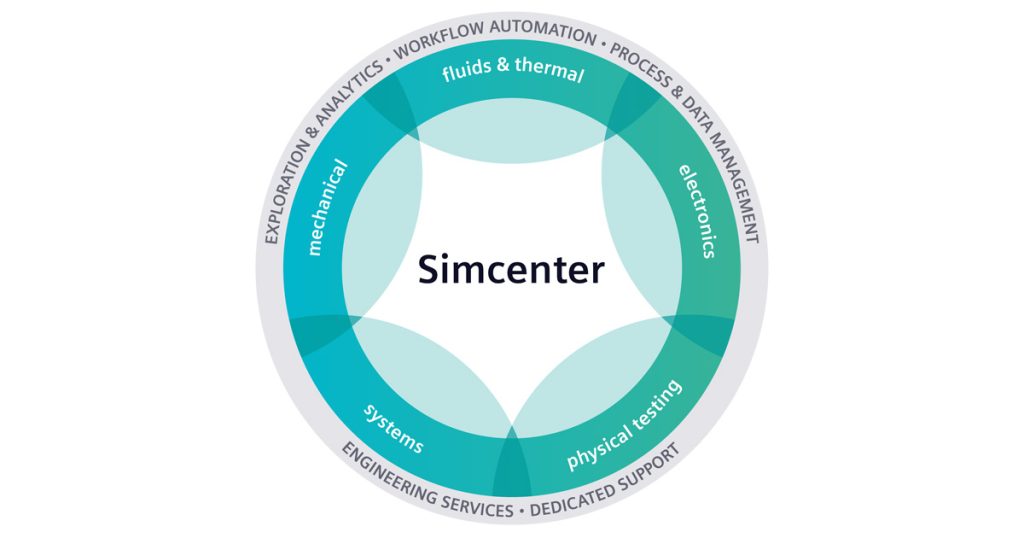

FloTHERM XT, a product from Mentor Graphics, which is now under Siemens ownership and offered as part of Simcenter, is an excellent software for simulating heat transfer in both internal and external flows.

This software is used for simulating hydrodynamics, liquids, and gases in various industrial components, particularly in electronic heat transfer and radiation.

FloTHERM XT is an ideal software for fully utilizing EFD and is a powerful solver for modeling heat transfer in any complex assembled component.

In fact, FloTHERM XT enables the complete modeling and simulation of hydrodynamic components and electronic parts, allowing for the examination of the final assembly.

This software allows you to import formats such as IDF, PADS, and more. It also includes a new module to create a direct relationship with the company.

Siemens Simcenter FloTHERM is a software that uses advanced CFD techniques to predict air flow, temperature, and heat transfer in components, boards, and systems such as racks and data centers.

Siemens Simcenter FloTHERM is the best software available on the market for integrating Mechanical Computer-Aided Design (MCAD) and Electronic Design Automation (EDA).

FloTHERM can be considered the undisputed pioneer in thermal analysis of electronics, with 98% of users recommending it to others. Features such as user resources, case studies, and technical papers published far exceed those of competing software.

Siemens Simcenter FloTHERM

FloTHERM can integrate with other well-known MCAD and EDA tools. The ability to import data in XML format simplifies model creation, problem-solving, and automatic result reporting.

The automatic sequential optimization of this software, along with its DoE capabilities, has reduced the time required to reach an optimal design while maintaining the design flow.

Engineers using Siemens Simcenter FloTHERM can focus on design and achieve the most accurate results within short timeframes.

The SmartParts section and the Cartesian structured approach have significantly reduced the problem-solving time for each cell in the table.

The “localized table” technique supports integration interfaces for matching, interference, and inconsistency between different areas of the software domain.

Features and Capabilities of FloTHERM XT: