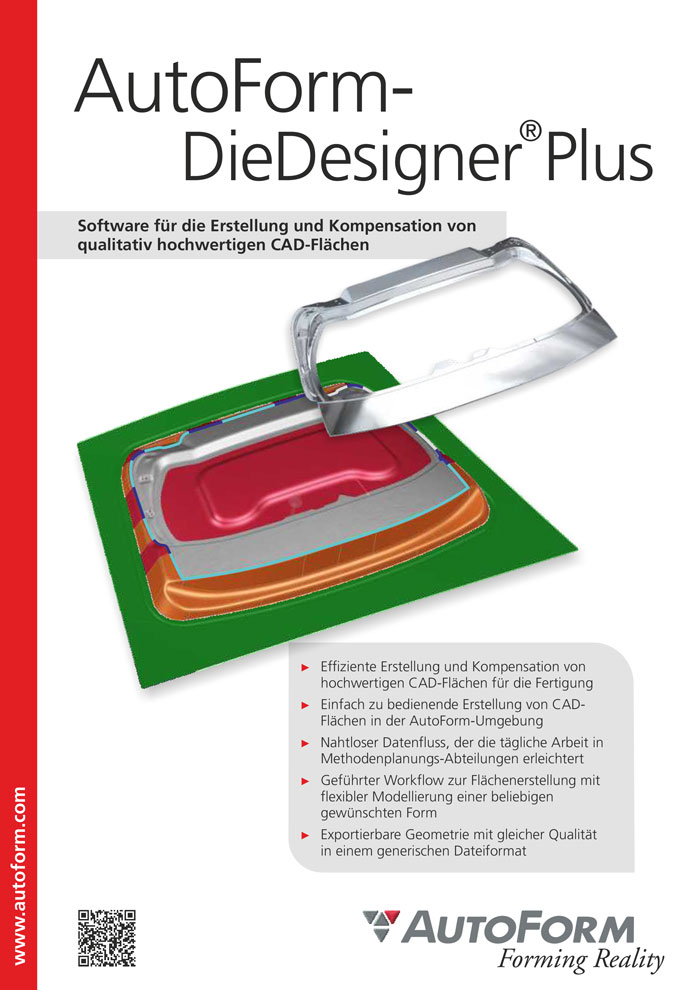

AutoForm provides advanced software solutions for sheet metal forming and shaping in various industries, especially in automotive manufacturing.

AutoForm is developed by one of the leading companies in providing practical software solutions for sheet metalworking and metal parts, including the production of automotive accessories.

The powerful features offered by this suite in the form of software modules, either independently or in combination with CATIA or NX, assist engineers across the entire industrial process chain of sheet metal processing (product design, mapping, forming, production, etc.).

Using these AutoForm software modules increases reliability in planning, reduces the time and number of test molds, and, as a result, makes the design of parts and industrial tools more quality-oriented and effective for production.

According to experts who have practically used these software modules, AutoForm forms a complete and integrated system with specialized functions for analysis, examination, and optimization of all phases of the sheet metal forming process.

AutoForm Plus

This software suite is for industrial product designers, metal forming engineers, industrial design implementation specialists, manufacturing engineers, and supervisors involved in sheet metal processes.

Features and capabilities of AutoForm software: