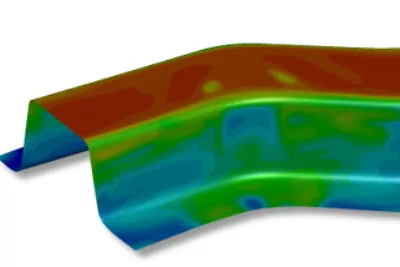

ANSYS Forming is a comprehensive simulation software that addresses the needs of various industries by allowing engineers to digitally simulate, design, and validate the metal sheet forming process. It helps reduce time and costs while improving precision and efficiency across multiple stages of metal forming.

ANSYS Forming is a powerful and versatile software that streamlines the metal sheet forming process across various industries. It enables engineers to quickly and accurately simulate, design, and optimize their metal forming processes, leading to reduced costs, improved productivity, and higher-quality products.