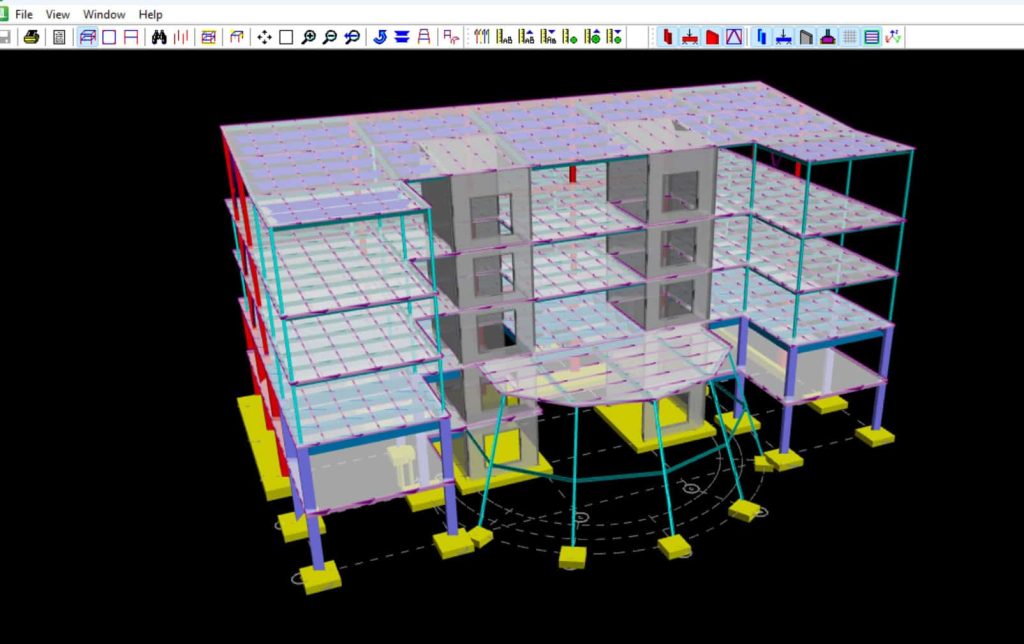

RAM Elements is a comprehensive set of structural analysis software from Bentley, specifically designed for the 3D design and analysis of steel and concrete structures.

This software is the most comprehensive structural analysis tool, primarily capable of analyzing steel and concrete structures.

It performs highly accurate calculations during design, providing the best results for civil engineers, municipalities, and architects. Beyond just 3D design capabilities, it also performs the dynamic analysis required for your projects.

The software provides advanced structural analysis tools for testing, with analytical capabilities broader than any other Bentley software.

RAM Elements is a powerful Bentley tool for planning and analyzing 3D structures.

This software allows you to design and simulate various structures and perform 3D finite element analysis.

RAM Elements simplifies daily planning for both simple and complex projects, saving valuable time and cost.

No matter how complex your project is, RAM Elements can handle steel, concrete, cold-formed steel, wood, stone, and more.

It enables you to design and construct structures and components. With this software, you can also design retaining walls, sloped walls, stone walls, and shoring walls.