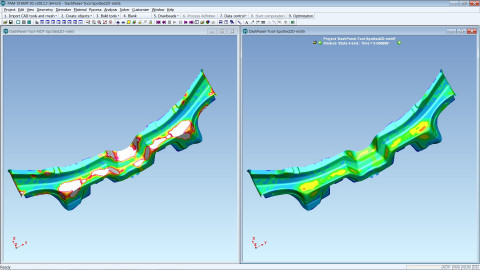

ESI PAM-STAMP is a powerful software designed for metal forming simulation, particularly for steel and aluminum sheet metal manufacturing. Released in 2017, this tool provides highly accurate simulations to optimize the stamping process, reduce costs, and improve production efficiency.

With a user-friendly interface, PAM-STAMP enables engineers to design and analyze metal forming processes efficiently, from die design to final part validation.

✅ Faster & More Accurate Simulations → Reduces errors and saves costs.

✅ Improved Workflow & Collaboration → Multi-user environment for efficient teamwork.

✅ Highly Scalable & Customizable → Works for both small-scale and industrial manufacturing.

✅ Realistic Virtual Reality Integration → Enhances visualization and process planning.

ESI PAM-STAMP is a cutting-edge tool for metal forming simulation, offering a comprehensive, efficient, and highly accurate solution for manufacturing engineers and designers.