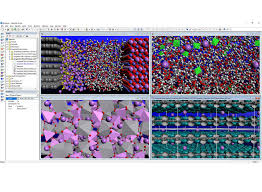

Materials Studio is a comprehensive molecular simulation software designed to assist researchers in chemistry and materials science with predicting, understanding, and analyzing the properties and behaviors of various materials. It offers advanced modeling and simulation tools to explore a wide range of molecular structures and materials, including polymers, nanomaterials, organic and inorganic compounds, and crystals.

Materials Studio is a powerful and versatile software tool for researchers and scientists in the fields of chemistry, materials science, and nanotechnology. It enables the study and simulation of molecular structures, materials, and complex systems through advanced techniques like DFT, Molecular Dynamics, and Monte Carlo simulations. Its modular structure, predictive capabilities, and user-friendly interface make it an essential tool for accelerating research, reducing costs, and improving the accuracy of predictions in material development and design.

Request a supercomputer!

Related links

List of software in economic management industries

Analysis of Mathematical software

Analysis of Management and economics software

Analysis of electricity and electronics softwares

Analysis of existing software in Architectural engineering

Analysis and classification of Mechanical Engineering software