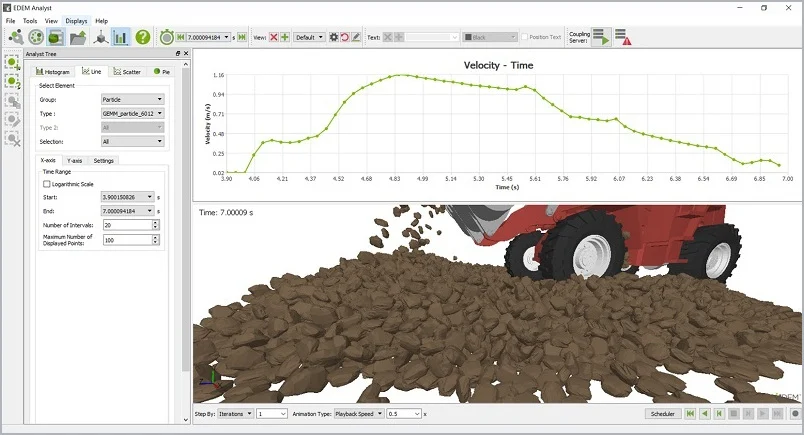

EDEM is one of the leading software programs for simulating bulk materials (such as coal, soil, sand, gravel, etc.).

EDEM software, using discrete element modeling (DEM) technology, enables fast and accurate modeling of discrete elements for the simulation and analysis of the behavior of these materials.

Essentially, EDEM software provides engineers with a deeper understanding and insight into how materials interact with machinery, tools, equipment, processes, and various mechanisms.

Altair EDEM Professional is a powerful, well-known, and unique software product for large-scale simulation of bulk materials using discrete element modeling (DEM) technology.

This software can quickly and accurately simulate the required amount of various materials such as coal, ores, soil, shale, and dust, making them available for analysis.

As you know, an important part of the design, analysis, and simulation of various components and materials in the industry is currently carried out with the help of software products.

Using these tools, you can evaluate the probable outcome of a case more realistically and achieve a predictable result without wasting time and money.

From this perspective, industries such as agriculture, mining, road construction, chemistry, and metal powders benefit from one of the most powerful and comprehensive tools available for simulating materials.

This program uses the DEM method for simulation and equation solving. This method is specialized for handling a large number of small particles and, therefore, presents an ideal solution for simulating bulk materials with the highest possible accuracy.

Altair EDEM is an advanced software solution with specialized functions for simulation in industries such as agriculture, mining, road construction, and for optimizing bulk materials in sectors like pharmaceuticals, chemicals, and metal powders.

This software is designed for analyzing the movement of materials from mines, factories, and conveyor facilities. Unlike other similar programs, it uses the Discrete Element Method (DEM) for performing simulations and solving equations.

This digital dissolution process is specifically designed for processing a large number of small particles, including metal powders, minerals, agricultural products, etc., making it highly suitable for bulk materials.

Some of the key features of this software in iron ore extraction and steel production include:

This software also includes exclusive features for the simulation and analysis of heavy machinery in road construction and agriculture, such as:

Let’s explore all the functional features of this program. EDEM has excellent potential for educational purposes.

Many multi-body engineering phenomena can be analyzed thanks to FEA, DEM, CFD, and MBD simulation tools, ranging from the simulation of particle motion in electronic components to photon impacts on metal surfaces.

Request a supercomputer!

Related links

List of software in economic management industries

Analysis of Mathematical software

Analysis of Management and economics software

Analysis of software in the field of physics

Analysis of electricity and electronics softwares

Analysis of existing software in Architectural engineering

Analysis and classification of Mechanical Engineering software