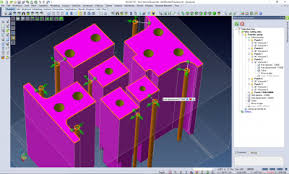

Vero VISI is one of the best 3D design, modeling, and analysis software tools for a variety of industrial applications, particularly in casting, injection molding, forging, die-casting, and stamping. It offers an integrated environment with robust features tailored to creating complex shapes and components with high precision.

Here are the key features and capabilities of Vero VISI:

In summary, Vero VISI is a comprehensive CAD-CAM software solution that offers a range of advanced tools for modeling, simulating, and optimizing designs for industries like plastic injection molding, casting, and die-stamping. Its robust analysis, simulation, and electrode management capabilities make it a powerful tool for professionals in manufacturing and design.