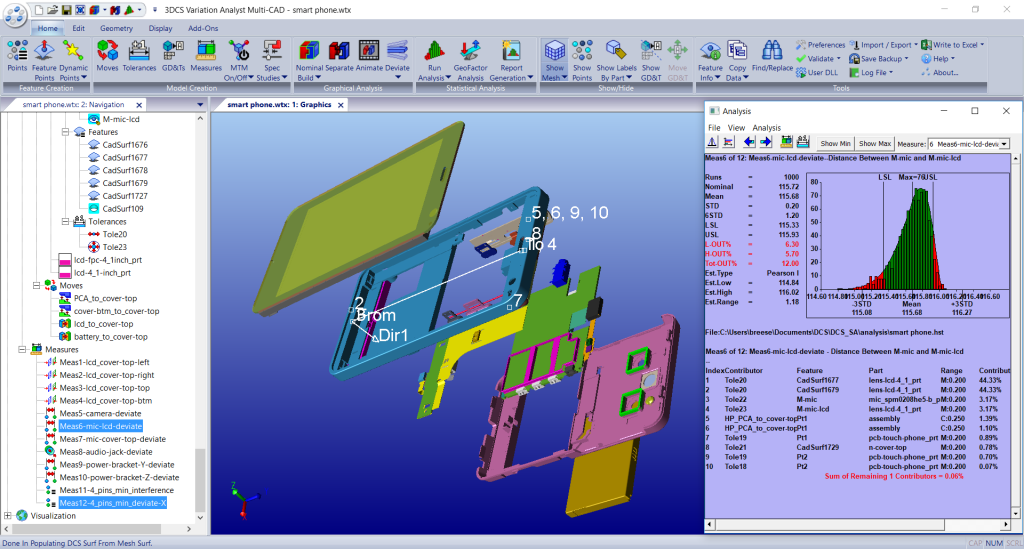

3DCS Variation Analyzer is one of the most powerful software tools for tolerance analysis, fully integrated into various CAD platforms. It provides engineers with accurate insights into their designs, helping them predict and measure dimensional and geometric variations in manufactured parts.

Tolerance analysis is a crucial process in mechanical engineering that:

Since design variations are inevitable due to manufacturing constraints, assembly processes, and material properties, tolerance analysis helps ensure product quality, performance, and manufacturability.

✔ Seamless CAD Integration – Works within leading CAD platforms like CATIA, NX, CREO, and SOLIDWORKS

✔ High Speed & Accuracy – Delivers precise analysis results quickly

✔ Monte Carlo Simulation – Uses three advanced simulation methods for statistical analysis:

By using 3DCS Variation Analyzer, manufacturers and engineers can achieve higher precision, lower costs, and improved product reliability, making it an essential tool for modern manufacturing and design optimization.