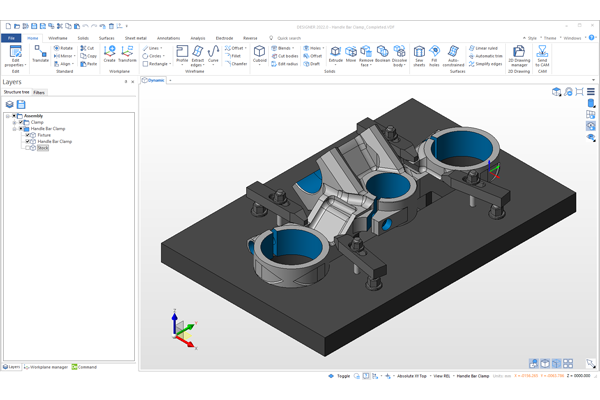

ESPRIT is a high-performance CAD/CAM software designed for programming, simulation, and optimization of CNC machining processes. It supports a wide range of manufacturing operations, including turning, milling, grinding, drilling, and wire EDM.

✅ CAD to CAM Conversion – Accurately converts CAD models into CAM toolpaths.

✅ High-Speed & Precise Simulation – Advanced 3D machining simulations ensure accuracy and efficiency.

✅ Multi-Axis Machining (5-Axis Support) – Reduces coding complexity and enhances precision.

✅ Smart G-Code Generation – Automatically generates G-code tailored to machine brand & type.

✅ Optimized Machining Strategies – Reduces unnecessary tool movements for better efficiency.

✅ EDM Wire Cutting & CNC Programming – Supports electrical discharge machining (EDM) and CNC automation.

✅ Supports Various File Formats – Easily imports and processes CAD files from different software.

✅ Comprehensive Manufacturing Operations – Handles turning, milling, grinding, sanding, and drilling.

🚀 Fast & Efficient Programming – Reduces machine downtime and improves productivity.

💡 Accurate Machining Simulation – Minimizes errors before actual production.

🔧 Seamless CAD/CAM Integration – Works with industry-standard CAD software.

📉 Cost Reduction – Optimized toolpath strategies lower production costs.

🛠 Scalable for Various Industries – Suitable for automotive, aerospace, and industrial machining.

With ESPRIT, manufacturers and CNC programmers can enhance efficiency, reduce programming time, and ensure precise machining, making it one of the best choices for modern manufacturing workflows.